Reactive Dyes For Textile Printing

GENERAL PROPERTIES

FASTNESS TEST METHODS

PRINTING

Reactive Dyes For Textile Printing

- Suitable for printing by roller flat screen & rotary screens

- Ease of print paste preparation

- Wide range of exceptional brilliance

- Good solubility

- Can be fixed by various methods

- Good all round fastness properties

| AN KIT “P” DYES | 100% Cotton Fabricat 120°C | % OF SHADE | GENERAL PROPERTIES | FASTNESS PROPERTIES | ||||||||

| AFFINITY | SOLUBILITY (PLAIN WATER) | DISCHARGEABILITY | WASH – OFF PROPERTIES | LIGHT (ISO 105-B02) | WASHING (150-105 CO3) | PERSPIRATION(ISO 105-E04) | RUBBING(ISO 105-X02) | |||||

| ALKALI | ACID | WET | DRY | |||||||||

| Yellow FGL |  |

3% | M | 100 | G | A | 4-5 | 4-5 | 2-3 | 2 | 4-5 | 4-5 |

| Golden Yellow R |  |

3% | H | 100 | G | A | 4-5 | 4-5 | 4-5 | 4 | 3-4 | 4-5 |

| Yellow P-4G |  |

3% | M | 100 | F | A | 4 | 4 | 4 | 4 | 3-4 | 4-5 |

| Orange P-3R |  |

3% | H | 100 | G | B | 4 | 4 | 4-5 | 4-5 | 3-4 | 4-5 |

| Red P-2B |  |

3% | M | 100 | P | B | 4 | 4 | 4-5 | 4-5 | 4 | 4-5 |

| Violet H-3R |  |

3% | H | 80 | P | A | 4 | 4 | 3 | 4-5 | 3-4 | 4-5 |

| Blue H-5R |  |

3% | H | 100 | P | B | 4 | 4 | 4 | 4 | 3-4 | 4 |

| Blue P–5R |  |

3% | H | 70 | P | B | 4 | 4 | 4 | 4 | 3-4 | 4 |

| Blue P-3R |  |

3% | H | 100 | P | A | 4-5 | 4-5 | 4 | 4 | 4 | 4-5 |

| Black HN |  |

6% | M | 80 | P | B | 4-5 | 4 | 3-4 | 3-4 | 3 | 4-5 |

GENERAL PROPERTIES

Solubility

Room temperature at 25oC

Stability of color paste

Color paste of 2% o.w.p. containing sodium bicarbonate of 2% o.w.p. is stored at about 35oC for two weeks.

Dyes showing the fall of depth within 10% comparing with unstored one is classified as A group and over 10% classified as B group.

Wash-off properties

Washing-off property is divided from the degree of staining on white ground at soaping stage on heavy shade printing, into the following groups.

A: Very excellent

B: Excellent

C: Somewhat poor

D: Poor

FASTNESS TEST METHODS

| Light | ISO 105-B02 | Light fastness was tested at the given standard depth. Blue scale (1-8 grade) |

| Washing | ISO 105 C06-C25 | 4g/l ECE reference detergent, 1g/l Sodium perborate, 30min, at 60oC |

| Perspiration | ISO 105-E04 | Acid solution : 0.5g/l L-histidine, 5g/l Sodium chloride 2.5g/l NaH2PO4.2H20, pH 5.5, 4hrs at 37oC Alkali solution : 0.5g/l L-histidine, 5g/l Sodium chloride 2.2g/l Na2HPO42H20, pH 8.0, 4hrs at 37oC |

| Rubbing | ISO 105-X12 | Upper – dry, Lower – wet |

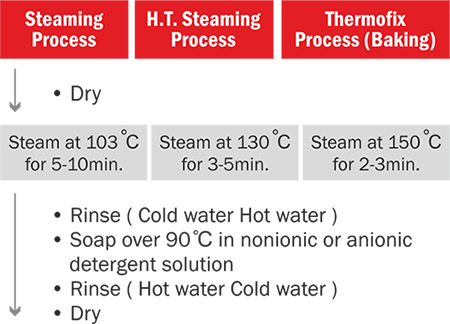

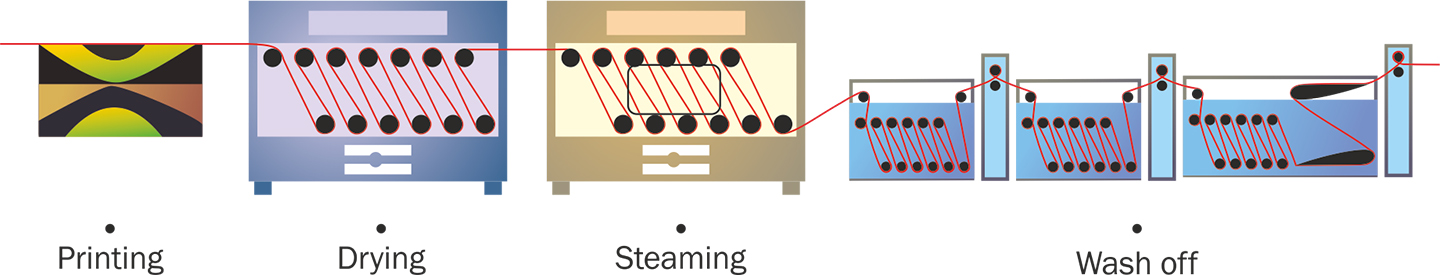

PRINTING

| Chemical pad (g/l) | Normal Steaming | HT Steaming | Baking |

| ANKIT | X | X | X |

| Urea | 50-100 | 100-200 | 100-200 |

| Water | Y | Y | Y |

| Stock paste (4-12%) | 400-600 | 400-600 | 400-600 |

| Reduction inhibitor | 20-Oct | 20-Oct | 20-Oct |

| Alkali | 30-Oct | 20-Oct | 20-Oct |

| Total | 1000 |